Description

|

Take advantage of Tax Section 179 Tax benefit

*** Warranty, Install and Training is Available ***

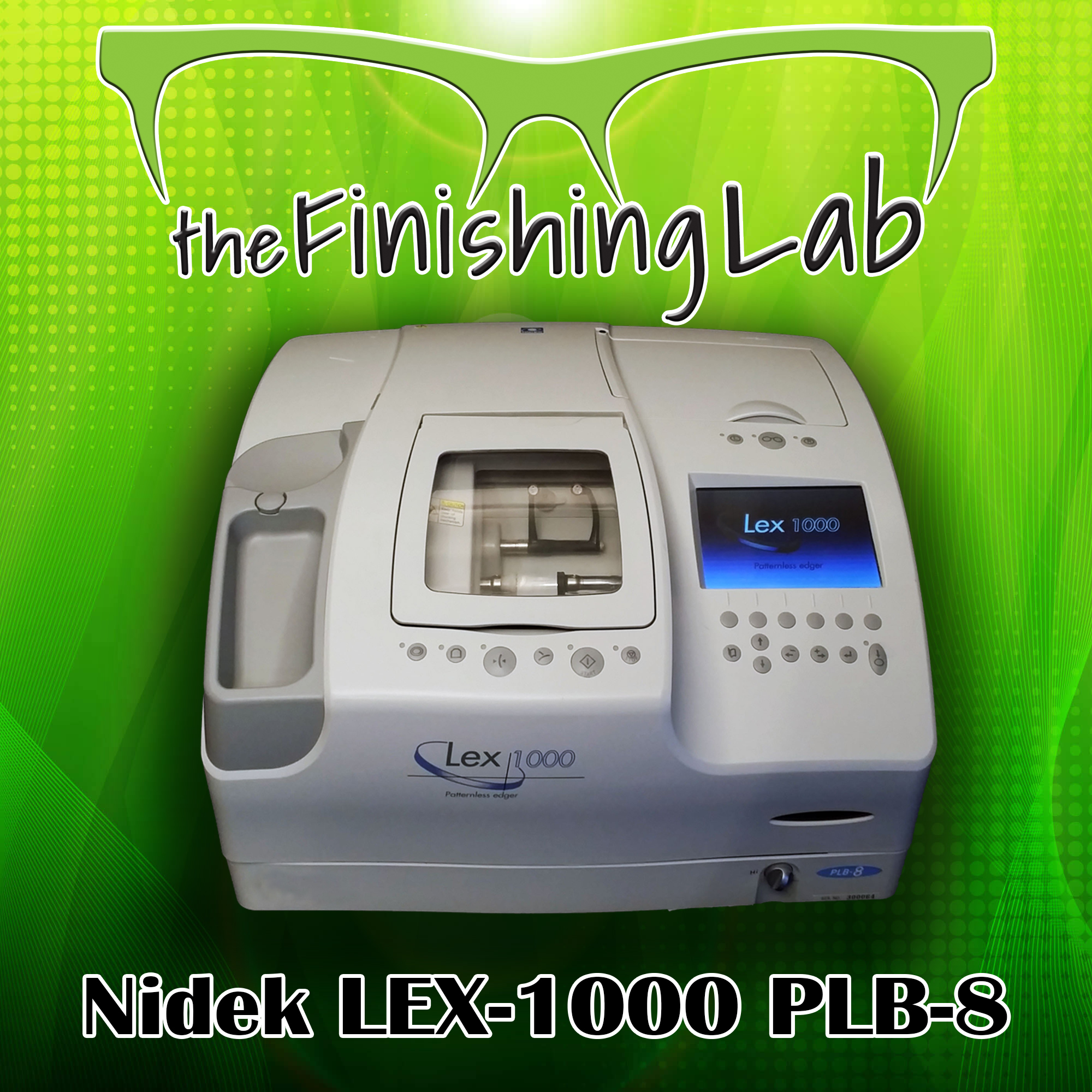

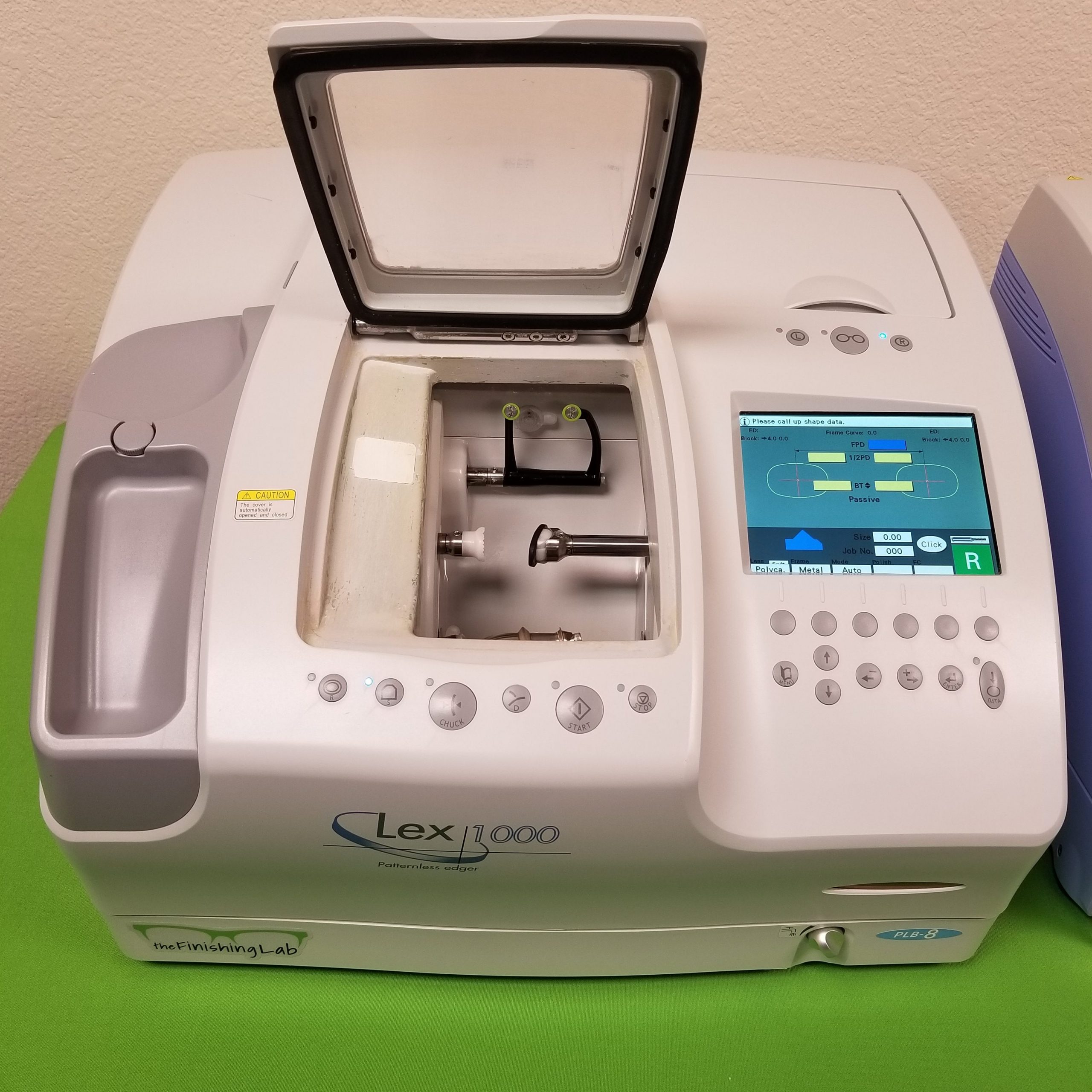

Santinelli Nidek LEX-1000 PLB8 Rimless Edger

Nidek’s new LEX Lens Edger Series features the highly intuitive LEX-1000 Edger, engineered with the most advanced technology available on the market. Its unique functions enable eyecare professionals to confidently handle even the most challenging jobs in-house to increase profits. It’s the world’s first retail edger to make glazing high base curve lenses simple.

Features:

- Minimum B measurement of 15.5mm for today’s smaller frames

- Minimum 15.5 mm “B” dimension can be processed with the new Nano Cup/Block. You can process super hydrophobic lenses without worry about axis shift with the use of the new pliable ring adapter

- Built-in fully programmable and adjustable high curve beveling

- Bevel set position can be put to front, rear or any position and ratio

- Can glaze up to 10 or 12 base lenses

- Grooves, safety bevels and polishes

- Cuts all lens materials

- Advanced soft grinding mode for processing super hydrophobic coats without the risk of slippage

- Five different system configurations, representing the widest array of choices available in the market.

Add on Drill: upgrade your system to rimless glazing at any time of your choice with the retro-fit LEX Drill.

High-quality drilling: 3D drilling from 0 to 30 degrees made easy, even challenging drilling such as twin holes, slots, rectangular holes, jewel holes or countersunk holes.

Slim design: at only 14.5cm wide the LEX Drill can fit into the smallest of Laboratories or Workshops.

Operation:

Information Bar: Even first-time users can easily operate the LEX1000 using the Information Bar which provides useful “next-step” information.

3-D Bevel Simulation: Sophisticated 3-D bevel simulation allows you to check the placement of the bevel as if viewing the actual lens from any selected angle.

Color-coded Lens Identi

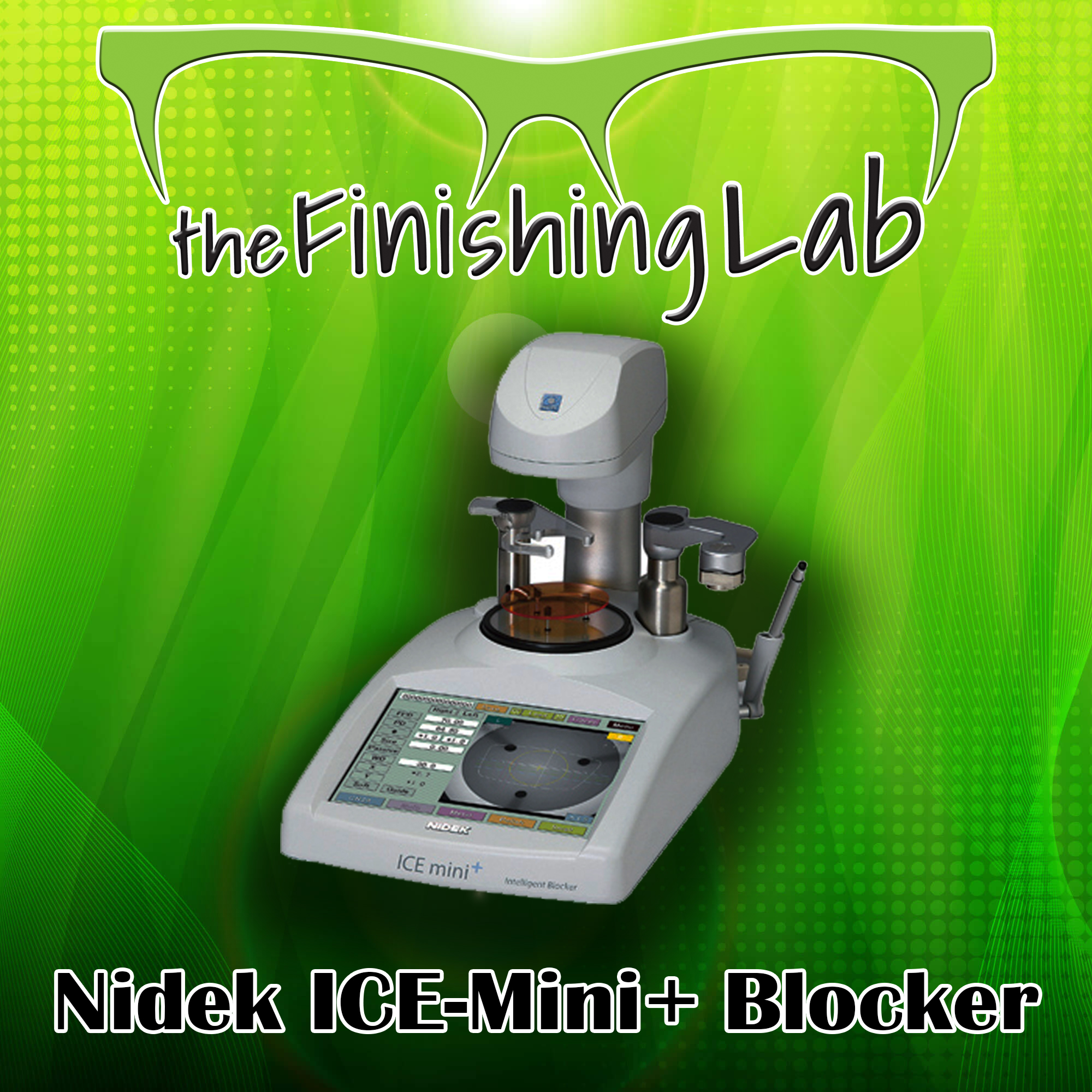

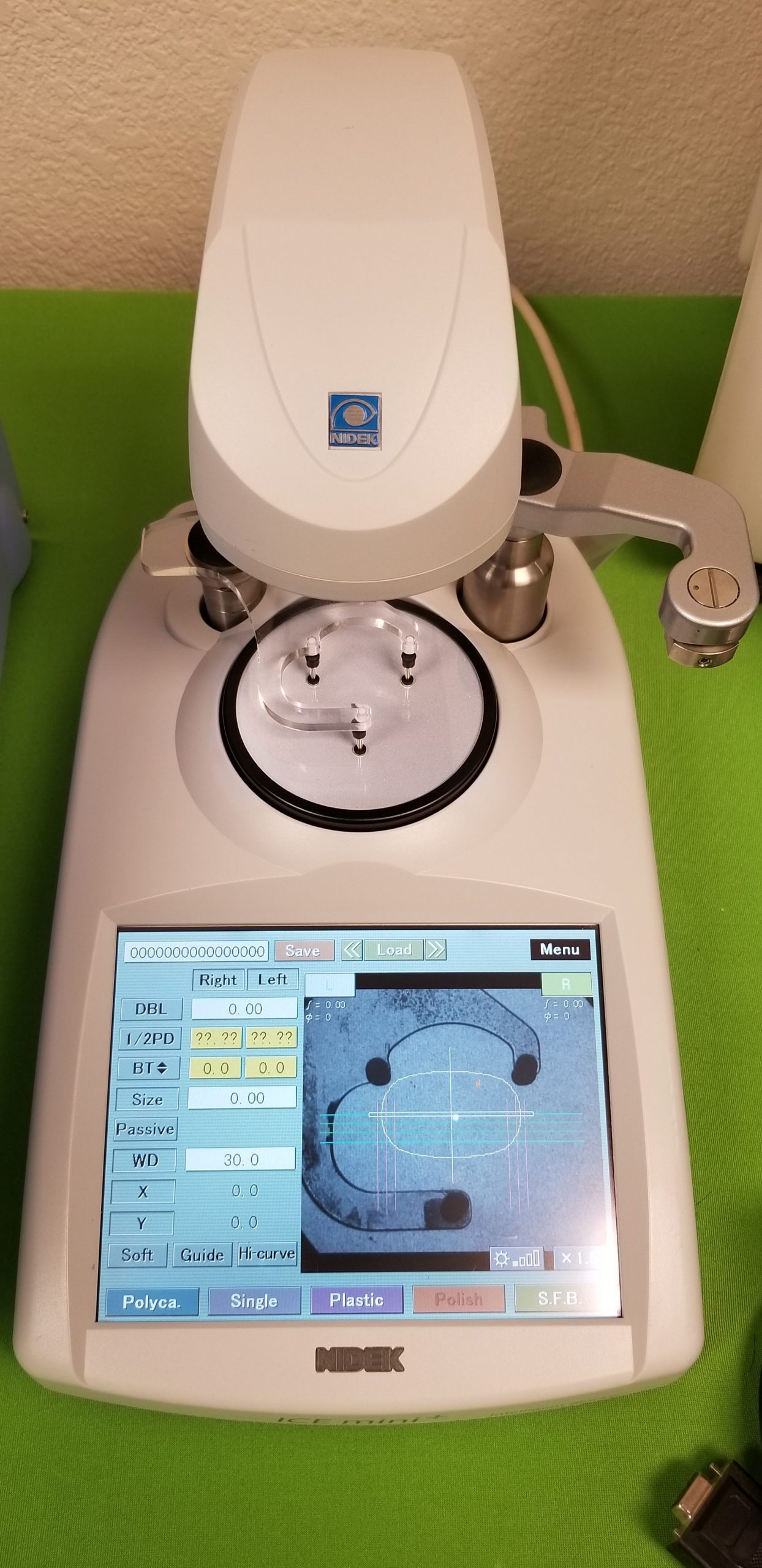

About the ICE-Mini Blocker

Blocking is easy and quick. For accurate and easy blocking for the operator, the 3-pin support lens is flexible and holds the lens from the top. The user-friendly color LCD touch panel is 8.4-inch and is easy to operate and offers clear display. Networking capability is versatile and the direct connection to the 2 lens edger is easy for the ICE mini. Blocking is as easy as 1-2-3 by the NEW ICE-Mini from NIDEK.

Step 1: On the table simply place the marked lens.

Step 2: Input all data on the LCD touch panel such as the type of lens, frame, grinding mode and the data of the lens layout that includes PD, FPD, size and height of optical center is the data to be input.

Step 3: Block with blocking arm.

Color-coded Lens Identification: To aid the lens edging process, the display of the Lex1000 utilizes a color-coding system adapted from navigational light colors, to identify right and left lenses: green represents the right lens and red represents the left lens. Red and green cups (blocks) are included. You can avoid processing the wrong lens by following the color-prompted indicator on the display.