The Finishing Lab believes in helping you take care of your Santinelli Nidek Edger to reduce down time and help your Edger run at the top of its game.

We want to help you ensure that your equipment receives the proper care to guarantee best performance. Please review our recommended maintenance procedures and see below for videos demonstrating professional edger servicing techniques and practices.

LE 9000/1000 & LEX 1000 Recommended Maintenance Procedures

Every Day:

□ Rinse grinding chamber out with water (I use a 1.25gal garden sprayer). Make sure to get behind the wheels

and SFB unit, be careful not to spray water in the top near the LMU.

□ Close tracer covers (use old Leap tape to clean out the Tracer tray).

□ Clean the outside of edger with soft towel. (Magic Erasers work AWESOME)

□ Clean door glass with warm soapy water and dry with a microfiber cloth. (Never keep door closed overnight)

□ Keep area around the edger dry and free from debris.

□ Turn power off when machine is not in use.

□ Check water amount in Tank and Pump.

Once a Week:

□ Rinse grinding chamber out with water

□ Calibrate the Tracer every Monday to keep your Edger on size!

□ Change the water and clean the Tank and Pump System every 30~40 job. Replace the nylon filter (sock) at the

end of the drain tube. Higher users may need to clean and refill your tank on a daily or twice weekly basis.

You can never change the water to much! If you edge mostly CR-39 and Hi-Index change the water more

often, if you do mostly Poly and Trivex change the sock more often.

Every Month

□ Rinse grinding chamber out with water

□ Open the top edger cover (with power cord unplugged) and perform the following:

□ Using three-in-one oil, place a few drops in center hole above right side chucking assembly.

□ Inspect for water leaks on interior of the Edger.

□ Clean black sensors with a Q-tip and a dab of alcohol.(weekly with high Trivex users)

□ Check and clear any debris from the LMU assembly and the SFB/Groove assembly.

□ Clean and lubricate the rubber seal on the right side of chucking shaft.

□ Lubricate the worm gear that the chucking assembly rides up & down on.

□ Vacuum out any lens debris in the interior of the Edger. Note: Do not use a blower.

Recommendation

□ Rinse grinding chamber out with water

□ Use only 3M Leap III blocking pads and a Pliable blocking system. This will almost eliminate slippage! On

A-B A/R coatings clean lenses free of dust and finger prints and use a 1712LSE Leap Tape. For C-D A/R

coatings clean lenses free of dust and finger prints and use the 1712N Leap tape (only available through

Santinelli) place paper side to the block and the cellophane side to the lens. (do not use secure edge plus)

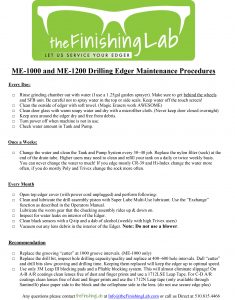

ME-1000 and ME-1200 Drilling Edger Maintenance Procedures

Every Day:

□ Rinse grinding chamber out with water (I use a 1.25gal garden sprayer). Make sure to get behind the wheels

and SFB unit. Be careful not to spray water in the top or side seals. Keep water off the touch screen!

□ Clean the outside of edger with soft towel. (Magic Erasers work AWESOME)

□ Clean door glass with warm soapy water and dry with a microfiber cloth. (Never keep door closed overnight)

□ Keep area around the edger dry and free from debris.

□ Turn power off when machine is not in use.

□ Check water amount in Tank and Pump.

Once a Week:

□ Change the water and clean the Tank and Pump System every 30~40 job. Replace the nylon filter (sock) at the

end of the drain tube. Higher users may need to clean and refill your tank on a daily or twice weekly basis.

You can never change the water to much! If you edge mostly CR-39 and Hi-Index change the water more

often, if you do mostly Poly and Trivex change the sock more often.

Every Month

□ Open top edger cover (with power cord unplugged) and perform following:

□ Clean and lubricate the drill assembly piston with Super Lube Multi-Use lubricant. Use the “Exchange”

function as described in the Operators Manual.

□ Lubricate the worm gear that the chucking assembly rides up & down on.

□ Inspect for water leaks on interior of the Edger.

□ Clean black sensors with a Q-tip and a dab of alcohol.(weekly with high Trivex users)

□ Vacuum out any lens debris in the interior of the Edger. Note: Do not use a blower.

Recommendation

□ Replace the grooving “cutter” at 1000 groove intervals. (ME-1000 only)

□ Replace the drill bit, inspect hole drilling capacity/quality and replace at 400~600 hole intervals. Dull “cutter”

and drill bits slow grooving and drilling time. Keeping them replaced will keep the edger up to optimal speed.

□ Use only 3M Leap III blocking pads and a Pliable blocking system. This will almost eliminate slippage! On

A-B A/R coatings clean lenses free of dust and finger prints and use a 1712LSE Leap Tape. For C-D A/R

coatings clean lenses free of dust and finger prints and use the 1712N Leap tape (only available through

Santinelli) place paper side to the block and the cellophane side to the lens. (do not use secure edge plus)

Edger Maintenance Reference Videos

Below are some reference videos created by The Finishing Lab to demonstrate professional edger servicing techniques and practices. Click on the video title to view the video.

Wheel Truing Cleaning for Finishing and Polish Wheels

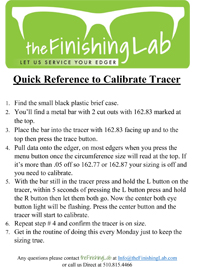

Step by Step Tracer Calibration

Leap Tape and Blocking System Review for Santinelli Edging Systems

Edger Maintenance PDF References Guides (Click to Download)

LE Series LEX-1000 Maintenance Procedures LE Series LEX-1000 Maintenance Procedures |

ME-1000 ME-1200 Maintenance Procedures ME-1000 ME-1200 Maintenance Procedures |

Quick Reference to Calibrate Tracer Quick Reference to Calibrate Tracer |